1.Lower cake moisture compared with other series.

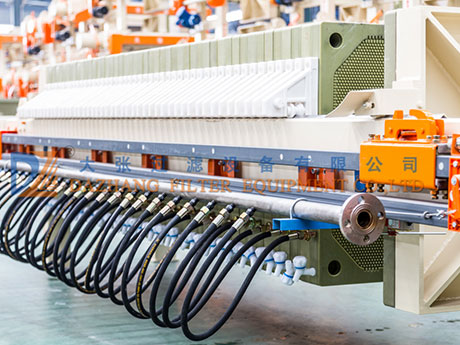

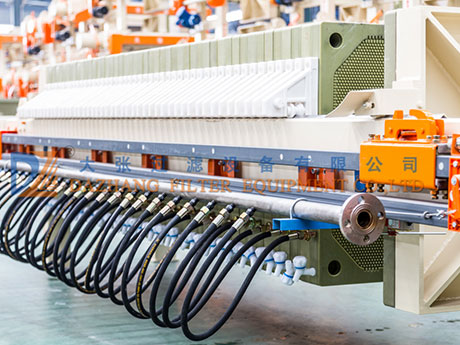

2.High pressure squeezing 1.6MPa is able to get more liquid extraction and higher cake dryness.

3.Fully Automatic program-controlled, Simple operation,Wide application

Slurry dewatering for wastewater treatment, Food&beverage, Chemicals, Mining, Medicine, Ceramic slurry, Metallurgy, print&dyeing etc

Nowadays, the membrane filter press is the market trend. The membrane filter plate has a three layers structure with a "sandwich" design, and it's hollow. Under the filter press pump's feed pressure, the filter cakes will be formed preliminarily, then high-pressure water or compressed air will be sent into the inside of membrane plates. Because the membrane plate inner pressure is higher than the filtering pressure, then the membrane will swell and squeeze the filter cake Reversely.

That's why the membrane filter press has lower cake moisture and better filtration performance.

Besides excellent filtering effect, membrane filter press is also suitable for fine particles and viscous materials. It can be recommended to users who have higher cake dryness requirements, such as following industries: mining concentrate, biological sludge,fine chemicals, etc... Our membrane plates are made from high-quality PP and TPE (Thermo Plastic Elastomer), so it has better elasticity and longer lifespan. Most importantly, it has very strong chemical stability which makes it applicable to many different industries. In addition, this filter press machine can meet demands on high efficient dehydration and deep dehydration.

1)Feeding pressure 0.6-2MPa, Hydraulic compressing, automatic maintaining pressure

2)Frame is made of high-quality Q345 carbon steel with sandblasting processing, it can be coated with SS304 or 316L for meeting high requirements like food grade, corrosion resistance etc.

3)Hydraulic system is equipped with famous brand motor, the power voltage can be customized as per customer's requirement from different countries, the closing pressure can reach 20-25MPa.

4)Control system uses Siemens PLC to realize automatic operation includes clamping, feeding, plate opening, plate shaking, cloth cleaning, cake discharging etc.

5)Schneider Electric components can work for many years. Stainless steel track for plate shifter is wearable, it has long service life.

6)Customized model, capacity and products are available

Click to expand to view the data

| Model | Filter press | Plate size | Cake thickness | Filter chamber volume | Plate NO | Filtration pressure | Motor power | Weight | Dimensions L*W*H(mm) | Foundation Size(mm) | ||||

| L | B | D | H | |||||||||||

| X_M^AG30/870−U_K^B | 30 | 870*870 | ≤35 | 498 | 23 | ≥0.8 | 2.2 | 3046 | 3880*1250*1300 | 2920 | 700 | 1270 | 785 | |

| X_M^AG40/870−U_K^B | 40 | 623 | 29 | 3593 | 4270*1250*1300 | 3300 | ||||||||

| X_M^AG50/870−U_K^B | 50 | 789 | 37 | 4057 | 4790*1250*1300 | 3820 | ||||||||

| X_M^AG60/870−U_K^B | 60 | 955 | 45 | 4597 | 5310*1250*1300 | 4340 | ||||||||

| X_M^AG70/870−U_K^B | 70 | 1121 | 53 | 5136 | 5830*1250*1300 | 4860 | ||||||||

| X_M^AG80/870−U_K^B | 80 | 1287 | 61 | 5636 | 6350*1250*1300 | 5380 | ||||||||

| X_M^AG50/1000−U_K^B | 50 | 1000*1000 | 776 | 27 | 4 | 4352 | 4270*1500*1400 | 3350 | 780 | 1400 | 870 | |||

| X_M^AG60/1000−U_K^B | 60 | 943 | 33 | 4480 | 4700*1500*1400 | 3780 | ||||||||

| X_M^AG70/1000−U_K^B | 70 | 1109 | 39 | 5263 | 5130*1500*1400 | 4210 | ||||||||

| X_M^AG80/1000−U_K^B | 80 | 1275 | 45 | 5719 | 5560*1500*1400 | 4640 | ||||||||

| X_M^AG100/1000−U_K^B | 100 | 1608 | 57 | 6555 | 6410*1500*1400 | 5490 | ||||||||

| X_M^AG120/1000−U_K^B | 120 | 1941 | 69 | 7466 | 7260*1500*1400 | 6340 | ||||||||

| X_M^AG80/1250−U_K^B | 80 | 1250*1250 | ≤40 | 1560 | 29 | 5.5 | 10900 | 4830*1800*1600 | 3960 | 850 | 1740 | 995 | ||

| X_M^AG100/1250−U_K^B | 100 | 1975 | 37 | 11750 | 5440*1800*1600 | 4570 | ||||||||

| X_M^AG120/1250−U_K^B | 120 | 2391 | 45 | 12600 | 6060*1800*1600 | 5180 | ||||||||

| X_M^AG150/1250−U_K^B | 150 | 2911 | 55 | 13620 | 6820*1800*1600 | 5950 | ||||||||

| X_M^AG160/1250−U_K^B | 160 | 3119 | 59 | 14470 | 7130*1800*1600 | 6255 | ||||||||

| X_M^AG200/1250−U_K^B | 200 | 3847 | 73 | 15320 | 8200*1800*1600 | 7325 | ||||||||

| X_M^AG240/1250−U_K^B | 240 | 4679 | 89 | 16170 | 9420*1800*1600 | 8550 | ||||||||

| X_M^AG250/1250−U_K^B | 250 | 4783 | 91 | 17020 | 9570*1800*1600 | 8700 | ||||||||

| X_M^AG200/1500−U_K^B | 200 | 1500*1500 | 3809 | 49 | 11 | 26120 | 7140*2200*1820 | 5870 | 1170 | 1990 | 1070 | |||

| X_M^AG250/1500−U_K^B | 250 | 4723 | 61 | 26930 | 7730*2200*1820 | 6860 | ||||||||

| X_M^AG300/1500−U_K^B | 300 | 5637 | 73 | 28160 | 8720*2200*1820 | 7850 | ||||||||

| X_M^AG350/1500−U_K^B | 350 | 6551 | 85 | 29600 | 10110*2200*1820 | 9090 | ||||||||

| X_M^AG400/1500−U_K^B | 400 | 7618 | 99 | 31500 | 11260*2200*1820 | 10240 | ||||||||

| X_M^AG450/1500−U_K^B | 450 | 8532 | 111 | 33400 | 12250*2200*1820 | 11230 | ||||||||

| X_M^AG500/1500−U_K^B | 500 | 9446 | 123 | 33380 | 13240*2200*1820 | 12220 | ||||||||

| X_M^AG600/2000−U_K^B | 600 | 2000*2000 | 11901 | 85 | 15 | 54164 | 13030*3000*2500 | 10610 | 1660 | 2000 | 1050 | |||

| X_M^AG700/2000−U_K^B | 700 | 13838 | 99 | 58300 | 14390*3000*2500 | 11920 | ||||||||

| X_M^AG800/2000−U_K^B | 800 | 14945 | 107 | 62460 | 15770*3000*2500 | 13240 | ||||||||

| X_M^AG900/2000−U_K^B | 900 | 17713 | 127 | 66620 | 17150*3000*2500 | 14560 | ||||||||

| X_M^AG1000/2000−U_K^B | 1000 | 19651 | 141 | 70780 | 18530*3000*2500 | 15880 | ||||||||

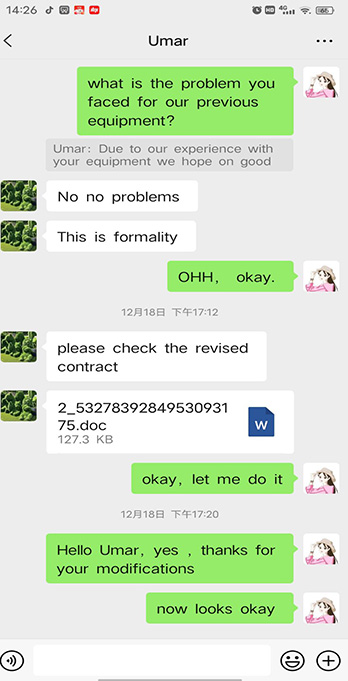

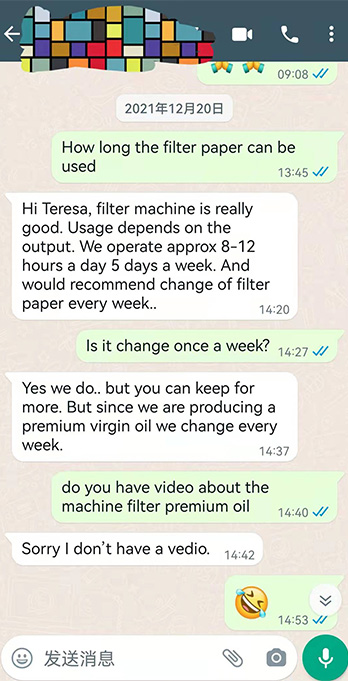

1000 engineers will always provide service for your project

In 2 hours, contact and give clear solutions

Provide the required information, product, site planning drawings, etc. timely

Slove the problem completely,inlcuding product installation,tech training service,spare parts,on-site maintenance, etc.

Thank you for visiting our website. If you have any needs or questions, please fill in the following, we will contact you in time