Filter press is commonly used solid-liquid separation equipment. It uses the principle of physical squeezing to separate solids from liquids. The filtrate becomes clear, and the solids are pressed into cakes and discharged.

Application: It can be used for sewage treatment, mining, food processing, medicine and chemical industry, and papermaking, leather making, metallurgy, textile, ceramics and other industries.

Effect: The moisture content of the filter cake of Dazhang filter press can be as low as 15 %, and the filtrate is clarified and can be recycled, saving costs.

Dazhang filter press can be divided into different type filter press according to different filter plates, materials, and operations. Equipment can be customized, and we can refer to customer data to give professional solutions and product suggestions.

1.Lower cake moisture compared with other series.

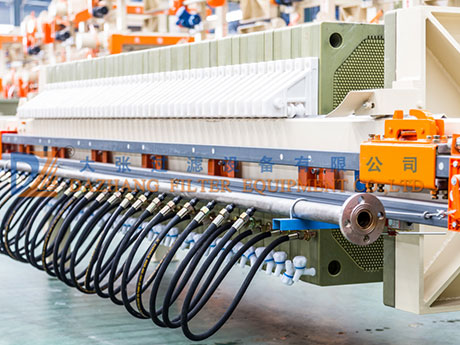

2.High pressure squeezing 1.6MPa is able to get more liquid extraction and higher cake dryness.

Membrane Filter Press

1.It can be used for ultra-filtration by using the filter paper, paperboard.

2.Various filtering medium for options: filter clothes or filter paper, paperboard

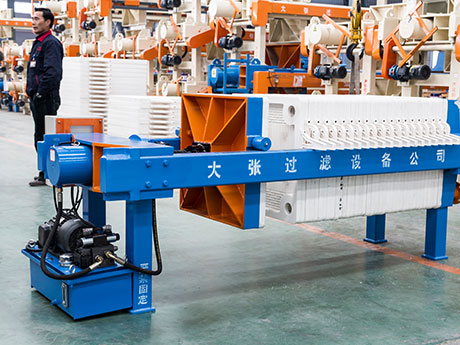

Plate And Frame Filter Press

1.Siemens PLC control and automatic cake discharging saves labor.

2.Higher dewatering and filtering efficiency.

Auto Filter Press

1.Need no power consumption.

2.Need no maintenance.

Manual filter press

1.High closing pressure (20-25MPa) can avoid leakage effectively.

2.Hydraulic powerback uses famous motor brand, it is steady in operation.

Hydraulic Filter Press

1.Resist high temperature and high pressure.

2.Meet the special standards in food and pharmacy industries

Stainless Steel Filter Press

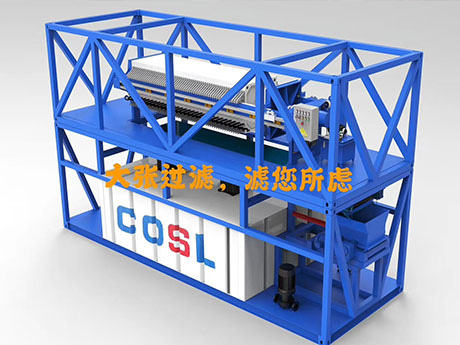

1.Simple and economical filtration through maximum flexibility and mobility

2.Compact and all in one design for trouble-free and reliable operation

Mobile Filter Press

1.specially developed for test filtration and laboratory analyses

2.integrated design, easy to move

Laboratory Filter Press

Advantages: 1. Easy to operate, labor saving; 2. Short filtration cycle and high efficiency 3. Simple operation, Wide application Applications: Slurry dewatering for wastewater treatment, Foodstuff, Chemicals, Mining, Medicine, Ceramic slurry, etc

Quick Open Filter Press

Advantages: 1. High strength, Resist high temperature and high pressure. 2. Cast iron material can ensure that it withstands the harsh working environment and maintain a long working life. Applications: Slurry dewatering for the oil industry and other industries which need high-temperature filtration.

Cast Iron Filter Press

Advantages: 1. Maximum feeding pressure 2.5MPa. 2. Lowest cake moisture. 3. Circular design plate has better mechanical performance. Applications: 1. Non-metallic mines: kaolin, and various clays. 2. Ceramics and porcelains: bone china tableware, electrical ceramic, ornamental porcelain, and so on.

Round Filter Press

Advantages: 1.larger filtration area. 2. Customized models and products are available Applications: Chemical, metallurgy, pharmacy, food&beverage, etc.

Cotton Cake Filter Press

Thank you for visiting our website. If you have any needs or questions, please fill in the following, we will contact you in time